It's always difficult to render visual thought processes into verbiage, so your pardon please, if the effort isn't always graceful.

The Great Lakes Beadworkers’ Guild was founded in 1992 by Christine Reilly from her Rags shop mailing list. I dimly (very dimly, if we're honest) recall sitting in a living room at the very first meeting, made of what came to be called the ‘core’ group and eventually mutated into the group's governing body. It was my hope that the Guild would foster cross-pollination of various beading techniques—at that time, beaded embroidery and stringing, since Rags was a costume supply shop and therefore its clientele bead and sequin embroiderers; I was one of the few stringers.

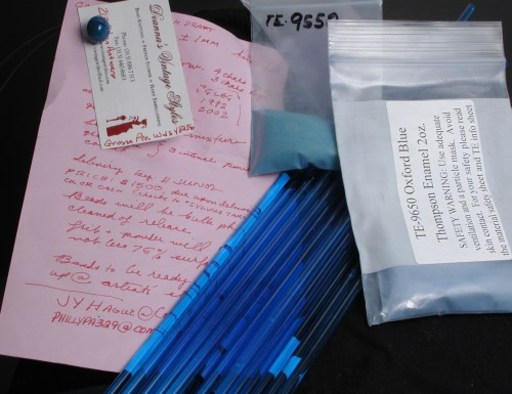

Some of the three pounds of dark aquamarine effettre rod, and bags of the three thompson enamels used to make the beads; the sample; and a rough copy of the contract for the beads.

My dream was to be fulfilled, at least for me: it is from the Guild, its members, and its programs, that I was exposed to, and learned how to do not only beaded embroidery, but also off-loom weaving techniques (beginning with 5 bead net, in my case), beaded knitting and beaded crochet and, from Peggy Prielozny, one of our out-of-state members, how to make glass beads.

This process came full circle, then, when the current board requested me to make a commemorative bead; that I was a founding member seemed all the more fitting. (The fact that I'm a production bead maker with relatively low prices probably didn't hurt either. What, you were expecting demure modesty in a promo piece?) I was—and remain—very honored and excited to be chosen.

My first task was to come up with some ideas. I did several for variety's sake, but focused on the frit and powder beads that are my favorites. (After all, it had to be a bead I was willing to make 300 times.) Given the Guild's name and past promotional materials, a blue color scheme seemed most appropriate. But the blue and white beads I made up were boring, so I decided I needed to keep developing the palette.

Having spent my childhood summers on the Detroit River, sailing, and participated in the Blue Water Ramble bike ride several times as an adult, I'd developed an appreciation for the green “weeds” in the water and beautiful foliage Michigan is blessed with in the Autumn. Greens with a little yellow reminescent of the yellowing grasses of Fall provided a color scheme consonant with the blue base yet having some visual zing. I made several versions of this bead on various base glasses. The Commemorative bead committee, which was immediately able to follow my reasoning for the color scheme, particularly the reasoning for adding the yellow for ‘snap’, selected a deep aquamarine which I certainly felt was perfectly appropriate—our lakes do have sort of a blue green cast to them!

Traditionally, I put metallic leaf on my abstracts, but I suggested substituting a signature cane on the bead, with the Guild's initials and dates, instead. This avoided the silver/gold controversy, and truly made the bead ‘commemorative’, because only these particular beads would be marked with a special murrina. In fact, I hope to register the cane. The Commemorative Bead committee enthusiastically adopted this idea, and I felt, at last, I would have to use Loren Stump's instruction for making complex cane. In fact, the last cane I made, in his class, had four elements: two eyes, a nose and a mouth. This one would have twelve components, albeit the simpler lettern and number canes: GLGB/1992/2002, stacked in three layers.

A close up of the completed complex cane. Since this is about 10mm in diameter, it would have to be pulled down to actually use...but it's a lot easier to read.

It also would be a much bigger cane than I'd ever pulled, about the size of a tennis ball. Having a blob of molten glass the size of your fist doing its best to distort itself into a mess, sag off the punty (handles) onto the table all while radiating two thousand or so degrees of intense heat is a charming experience I'd be happy to recommend to anyone. (Not.) Even with the hotter lynx torch, I believe it took me well over two hours to assemble, case and pull the cane; and by the end, my arms were very tired; and my hands were very hot; and I was very grateful to my long suffering spouse, who helped me pull the cane. Though I did properly wait for the huge gob (huge to me, anyway) of glass to cool and form a skin, being unfamiliar with how much heat it held, I didn't wait long enough.

I used well over a pound of yellow glass alone, just to make the cane. The dishes show some of the scrap, which is currently serving as marble practice. The canes shown are complex; the thinner ones were the size I actually used for the beads

So my cane stretched...and stretched...and stretched—to opposite sides of the basement and around the ladder (handy non-flammable object) and back to the torch. It pulled down, for the most part, to about 1/8”, just about exactly what I was looking for. During the session, I went through 500 lbs of oxygen (from a 125 cu/ft tank) and nearly fried a hole in my hood, which hadn't really been designed with flames the length of an Italian sausage in mind.

Close up of a bead with murrina. I attempted to get a shot of the murrina to blow up, but even a 3.34 megapixel camera with macro capabilities isn't quite there yet.

All this to make murrini in which the letters are so small they can't be read with the unaided eye. (This was deliberate: after all, you don't sign your name across half the painting—you put it discreetly in the corner. In fact, usually cane is made with black, actually transparent dark purple—and white—glass. But I chose yellow, so it would match the rest of the bead better. Often, however, I didn't melt the the murrina in completely, so it would show a little. But just a little: this bead was designed first and foremost to be a useable design element, not a novelty too weird to do anything but sit on a shelf.) I had enough cane, probably, to make three thousand, let alone three hundred beads. But on the other hand, I felt ready to tackle cane again, something I haven't done regularly in years!

I made approximately 307 signature cane beads. Two had spalled holes and had to be discarded; one I kept to make up something to show for the 10th anniversary meeting, Tuesday, June 18th; and the remainder I turned over to the Bead committee, along with a piece of signature cane, for the guild's collection. I look forward to seeing all those beads incorporated into larger projects!

29nov19: edited subtitle, minor formatting changes

Unless otherwise noted, text, image and objects depicted therein copyright 1996--present sylvus tarn.

Sylvus Tarn